-

The quality of the functional film and medical patch process is a single platform

UniEye's film and patch process inspection system inspects coating thickness, substrate thickness and defects at high speed and high precision for functional films and pharmaceutical adhesive patches used in R2R production environments.

By combining non-contact thickness measurement using a transmissive sensor and high-resolution camera-based foreign matter/defect inspection, production quality can be secured in real time.

-

Key Features

- Precise measurement of coating film and multilayer film thickness (Sub-micron correspondence)

- Automatic detection of defects such as air bubbles, foreign substances, scratches, etc

- Examination of medication coverage and thickness uniformity of medical patches

- Recipe-based settings, advantageous for multi-variety process conversion

-

Applicable industries

- Optical film for display, polarizing film

- Secondary Battery Electrode Coating Process

- Medical pain relief patches, transdermal drug patches

- laminating film, EMI shielding film

-

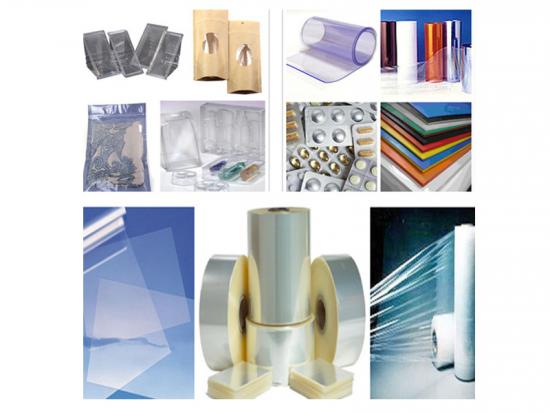

Print inspection system

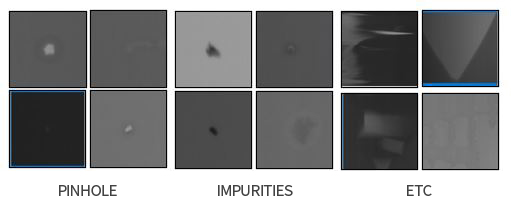

Inspects impurities and defects on material surfaces during various R2R printing processes

Impurities, pinhole, stain, scratches, etc.

-

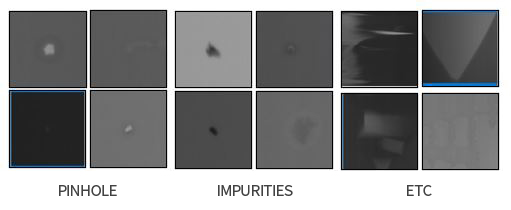

Print pattern inspection system

Inspects printing status of patterns during various R2R print processing, e.g. film, MLCC

W〮L margin, impurities, pinholes, smearing, no print, and sheet folding

-

Inspection system for application status

Measures application status and amount of application solution, e.g. resin, glue, PCB coating solution, and floor coating solution

-

Inspection system for film status

Inspects impurities and defects of film coating layers during film printing processes

Impurities, pinholes, stains, scratches, etc.

The instrument measures the amount of travel that occurs during film conveying.

-

Film Thickness Measurement System

Measures film thickness with OCT technology and spectrum analysis algorithm (thin film/thick film)

Provides table-top, offline, in-line types

- HOME

- APPLICATION

- Film Process Inspection