-

High-Speed Image Processing & R2R System Integration

UniEye provides essential high-speed image processing technology and integrated R2R (Roll-to-Roll) mechanisms tailored for continuous production environments. Through the unified design of sensors, optics, and mechanical structures, the system ensures stable image acquisition and real-time defect detection—even under high-speed material movement and line vibration.

Key Technical Features

- High-speed image processing supporting line speeds of tens to hundreds of meters per minute

- Precision transport mechanisms that suppress film vibration and maintain accurate focus

- Inspection algorithms that compensate for material deformation and dynamic motion

- Optimized combinations of various line-scan system components for specific process needs

-

Multi-Modal Thickness Measurement Technologies

UniEye selects the most suitable thickness measurement method based on product characteristics and process conditions to ensure precise and reliable thickness data. To support a wide variety of inspection targets—including transparent/opaque, single/multi-layer, and thin/thick materials—UniEye flexibly applies Interferometry, Confocal, and Laser Displacement sensor technologies.

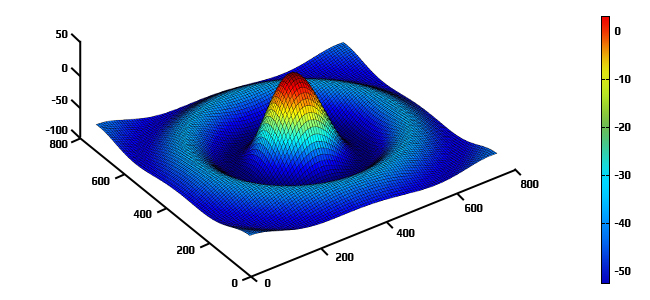

✔ Interferometry-based Measurement (Interferometry, OCT)

- Measures transparent thin-film thickness at the nanometer scale using light interference

- Ideal for high-precision applications such as multi-layer films and coating layers

- Well-suited for environments with mechanical vibration

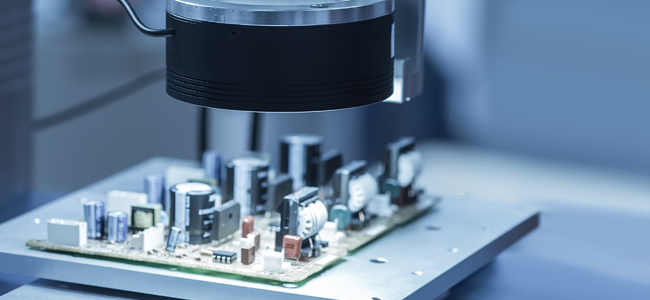

✔ Confocal Method

- Measures thickness using reflected light at a specific focal point

- Compatible with semi-transparent materials such as glass and silicon

- More robust to external noise and simpler in optical structure compared to interferometry

✔ Laser Displacement Sensor

- Practical measurement method for high-speed moving lines

- Effective for opaque materials, single-layer films, and adhesive layers in patches

- Compact sensor design fits well in limited space installationsKey Technical Features

- Flexible sensor selection based on material and process characteristics

- Wide measurement range from sub-micron to several hundred microns

- Supports multi-layer detection and interface-specific thickness differentiation

- Non-contact, high-speed scanning enables continuous inspection without disrupting the process

-

Dedicated Deep Learning Framework for Machine Vision

Unlike general-purpose deep learning frameworks, UniEye's system is purpose-built for vision inspection environments. It focuses on practical functionalities for real-world applications, such as automatic defect tagging, learning from small datasets, and defect clustering for classification and prediction.

Key Technical Features

- Defect segmentation and classification

- Anomaly detection and optimized one-shot learning

- Integrated labeling tools and on-site inference UI for operators

-

2D Vision Technology Based on Advanced Optical Design

UniEye possesses advanced optical design technology optimized for various lighting conditions, material properties, and surface reflectivity. By flexibly configuring illumination systems—such as transmissive, reflective, coaxial, and polarized lighting—and combining them with high-resolution cameras and precision lenses, the system accurately detects micro-defects, pattern anomalies, and surface condition changes.

Key Technical Features

- Supports a wide range of surfaces including multi-layer films, glass, metals, and medical materials

- Integrated design of lighting, lens, and camera for improved system stability

- Flexible optical customization considering reflectivity and refractive index variations

-

Flexible S/W Framework for Machine Vision Inspection

UniEye’s vision software framework is designed with a modular architecture to support a wide range of production processes and product types. Algorithms, UI components, and I/O configurations can be flexibly combined based on inspection targets and conditions, making it instantly deployable in both high-mix low-volume production and R&D environments.

Key Technical Features

- Block-based algorithm configuration (supports rule-based and AI hybrid structures)

- Recipe-based parameter saving and restoration

- Dynamic and visual representation of operational workflows -

Optimized Hardware Architecture for Vision Systems

UniEye designs dedicated hardware platforms optimized for high-performance image processing. Cameras, lighting, sensors, processing modules, and interfaces operate within a unified architecture, enabling low-latency data handling, high-speed synchronization, and minimized noise.

Key Technical Features

- Integrated design of camera and illumination modules

- Heat and noise shielding structure with enhanced durability

- Supports multiple standard interfaces (GigE, CameraLink, CoaXPress, etc.)

-

Integration with Diverse IoT Systems

UniEye's inspection systems are designed not only as standalone equipment but also with integration into the entire production line and IT infrastructure in mind. Through real-time communication with various external IoT systems—such as MES, ERP, PLCs, robots, sensors, and cloud platforms—they enable data-driven inspection results, automated control, and remote diagnostics.

Key Technical Features

- Supports integration with PLCs and fieldbus protocols (EtherCAT, Modbus, OPC-UA, etc.)

- Enables automatic registration of inspection records via API integration with MES/ERP systems

- Transmits inspection results using MQTT or RESTful communication protocols

- Facilitates real-time data exchange with sensors and control devices

- Supports cloud-based remote monitoring and condition diagnostics

- Compatible with predictive maintenance systems in smart factory environments

- HOME

- TECHNOLOGY

- TECHNOLOGY