-

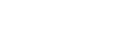

Modular platform with both flexibility and scalability in vision inspection configurations

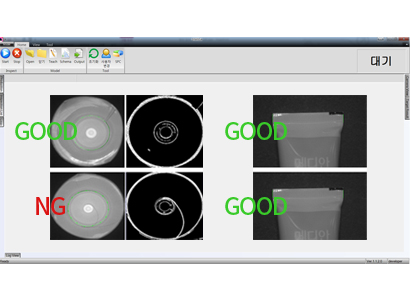

UniEye's Modular Vision System is a vision inspection solution that modularizes cameras, lights, lenses, algorithms, and more to flexibly configure them for different industries and product lines.

Through various sensor-based configurations such as fixed, line scanning, and 3D, you can quickly design and build an inspection environment that meets your customer's process conditions.

-

Key Features

- Maximize freedom of camera, lighting, and optical system composition

- Optical solution to product characteristics (reflective/refractive)

- AI or Rule-based inspection algorithm selectable

- Reusable platform structure for different processes and product lines

- Modular design for easy addition of maintenance and inspection items

-

Applicable industries

Various of customized products

-

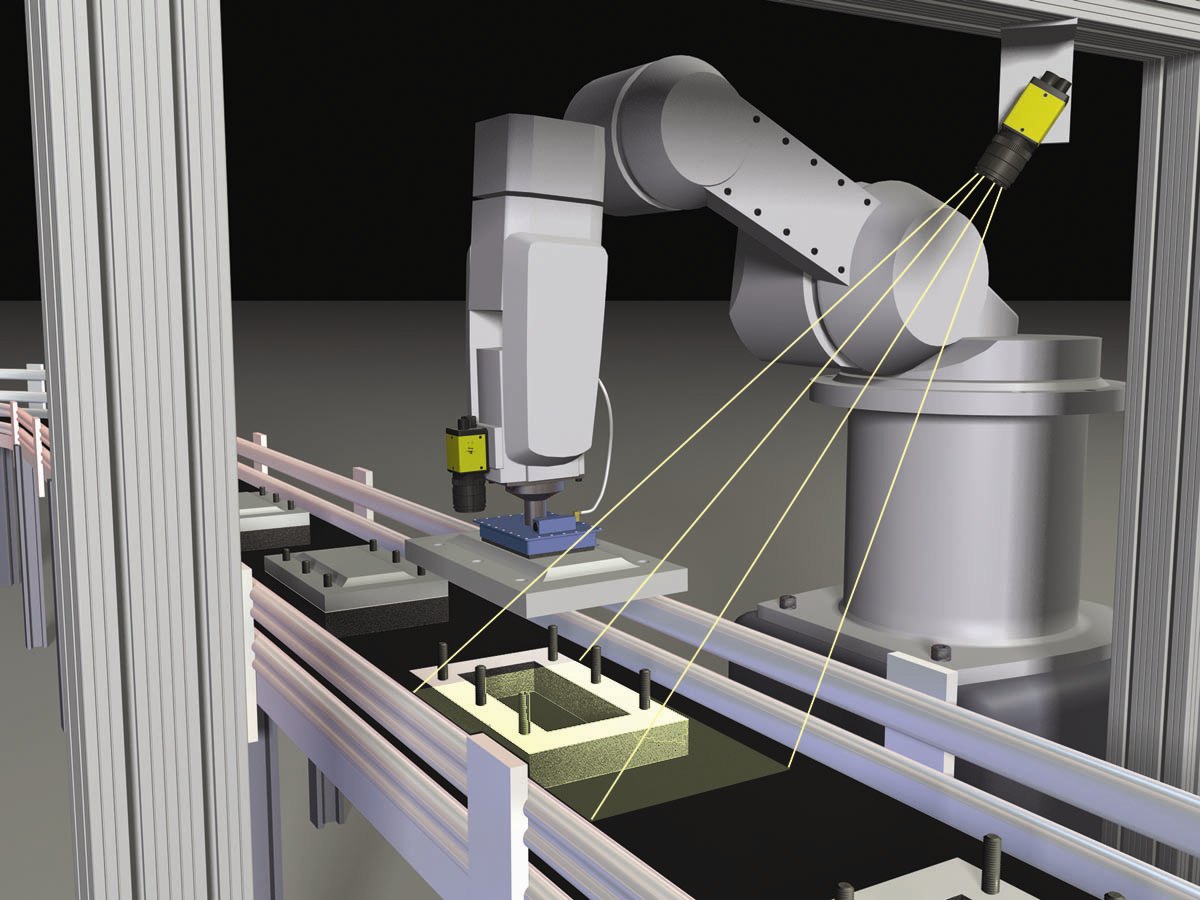

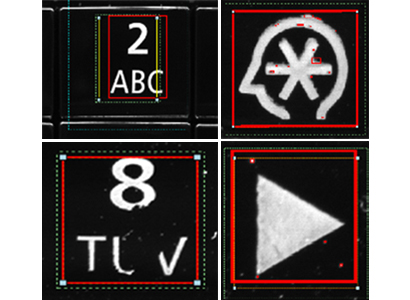

Charger Intermix Inspection

Sorts materials by OCR inspection to prevent charger intermix and mounts in the corresponding model box through Box Alignment

-

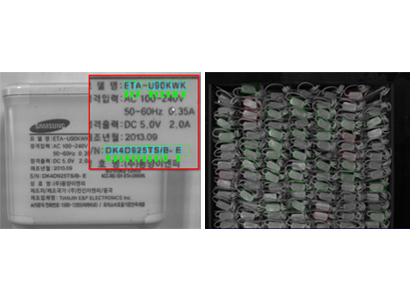

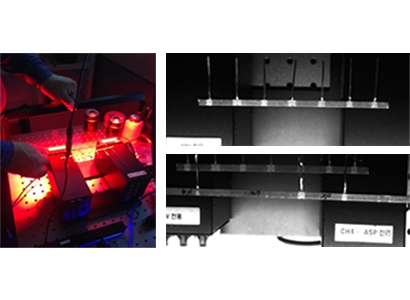

Frame Fastening Inspection

Assembly status inspection of frame connection area by measuring gaps in frame of Solar Panels

-

Tube Inspection

Inspects tube width, tube gap, impurities, and sealing using loop finding and edge algorithm, and amount of change in projection component of images

-

Barcode Inspection

Recognizes product barcode to prevent product intermixing

-

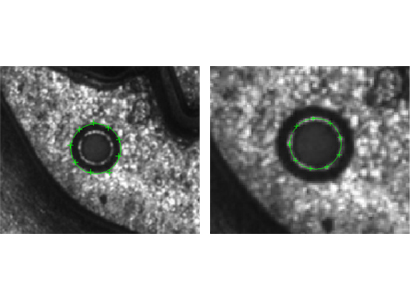

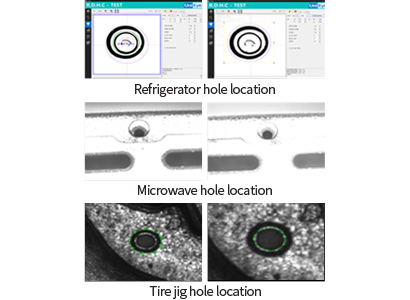

Tire Hole Align

Measures hole location tire jig using high-resolution CMOS camera and LED lighting and transmits to drilling rig

-

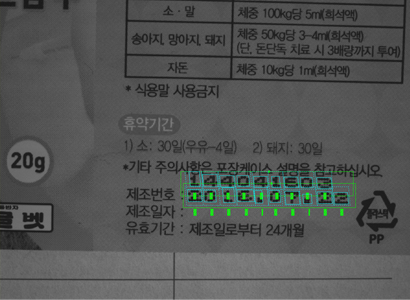

OCR/Barcode Inspection for Medicine Products

Inspects product manufacturing date, serial number through OCR/barcode and location calibration

-

Auto Bushing Viewer

For inspection of defects in the connection part and heating mark on the rear of the connection part after the bonding process between the cell strings in the solar panel production process

-

Panel Exterior Inspection

Exterior inspection of printer panel, e.g. leaning, cut/internal pinhole, misprint, and external impurities

-

Event Recording System

The system monitors operating state of inspection equipment to determine the status of inspection equipment whether it is in normal condition and enables rapid measurement in the event of problems.

-

Assembly Hole Location Measuring System

Measures locations of assembly holes by adopting lighting systems suitable for high- resolution camera and inspection characteristics and transmits to drilling equipment

Tire jig hole, microwave/refrigerator screw fastening hole, etc.

- HOME

- APPLICATION

- Modular Vision System